MODULE A – YOUR ENTRY INTO PHS TECHNOLOGY

Our Intensive Training in Press Hardening Module A gains access to everything, which is necessary for a safe and smooth start into press hardening technology.

The technological core of hot stamping, i.e. the integration of hot forming and heat treatment, is explained as well from a materials technology as from a process technology perspective. It constitutes a 4-day journey from theory to practice covering aspects e.g.

- state-of-the-art PHS application

- market developoment

- phase transformation, microstrucure & mechanical properties

- press hardening steels & coatings

- process monitoring & control

- selection of process parameters.

“In principle it’s simple – as long as you understand the theory behind it!”

Dr. Ursula Weidig, University of Kassel (GER)

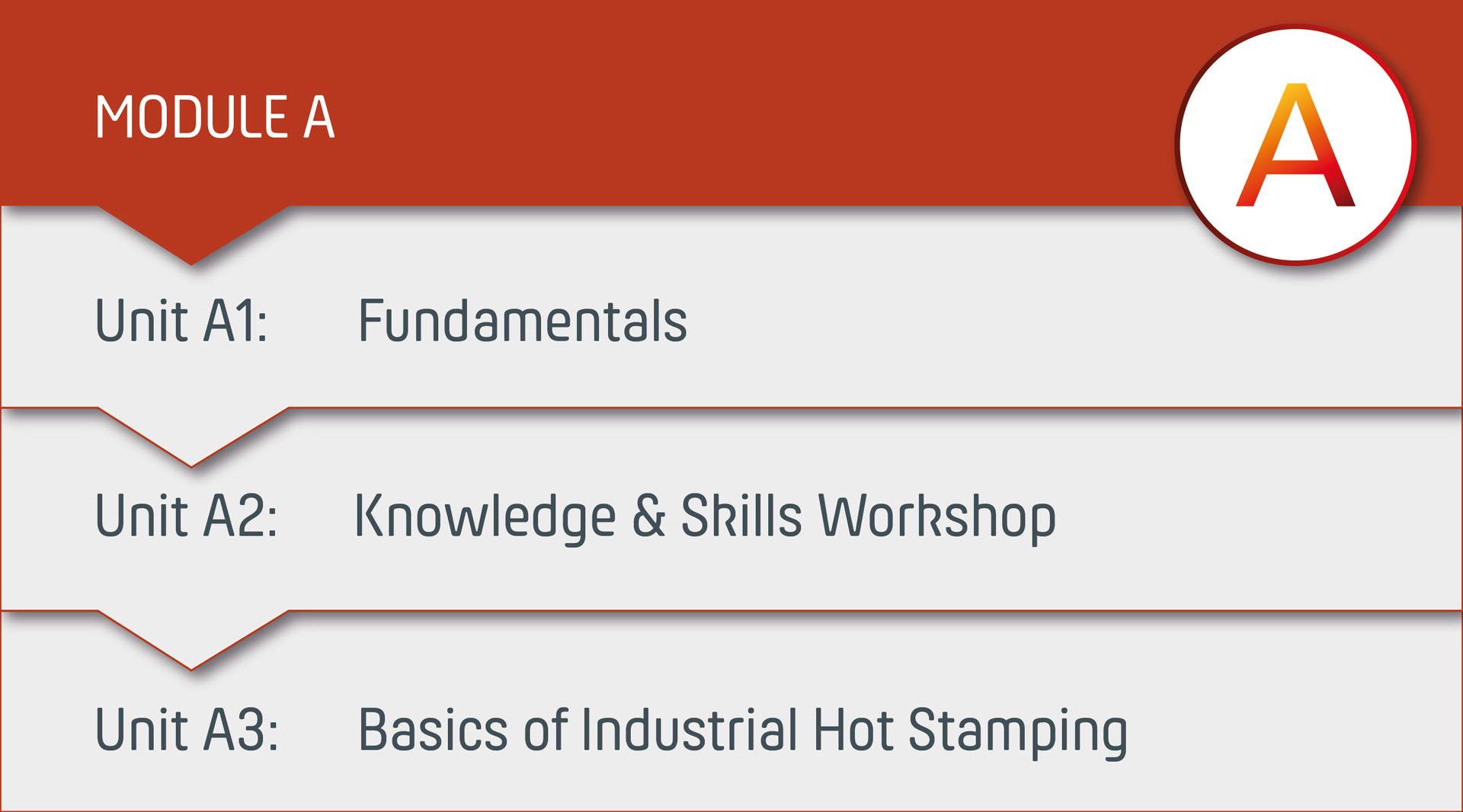

Line-up of learning units of Intensive Training in Press Hardening Module A

Since more than a decade the unique Module A line-up of contents has proven to be an effective measure to avoid rookie mistakes

MODULE B – INDUSTRIAL PRACTICE AT ITS BEST

If it comes to practical procedures on shop-floor level, quality of PHS components can only be maintained if highly specific procedures are fully understood, and, consequently applied.

The Intensive Training in Press Hardening Module B therefore puts special emphasis on aspects e.g.

- selection of process parameters for different PHS material systems

- process control

- temperature profiling & process monitoring

- materials testing equipment & procedures

- part quality & failure

- reliability and productivity of PHS processes.

“The real sport in PHS processing is it to keep an eye on everything – at any time! Finally it’s a question of skill and training.”

Agim Ademaj, PHS Trainer

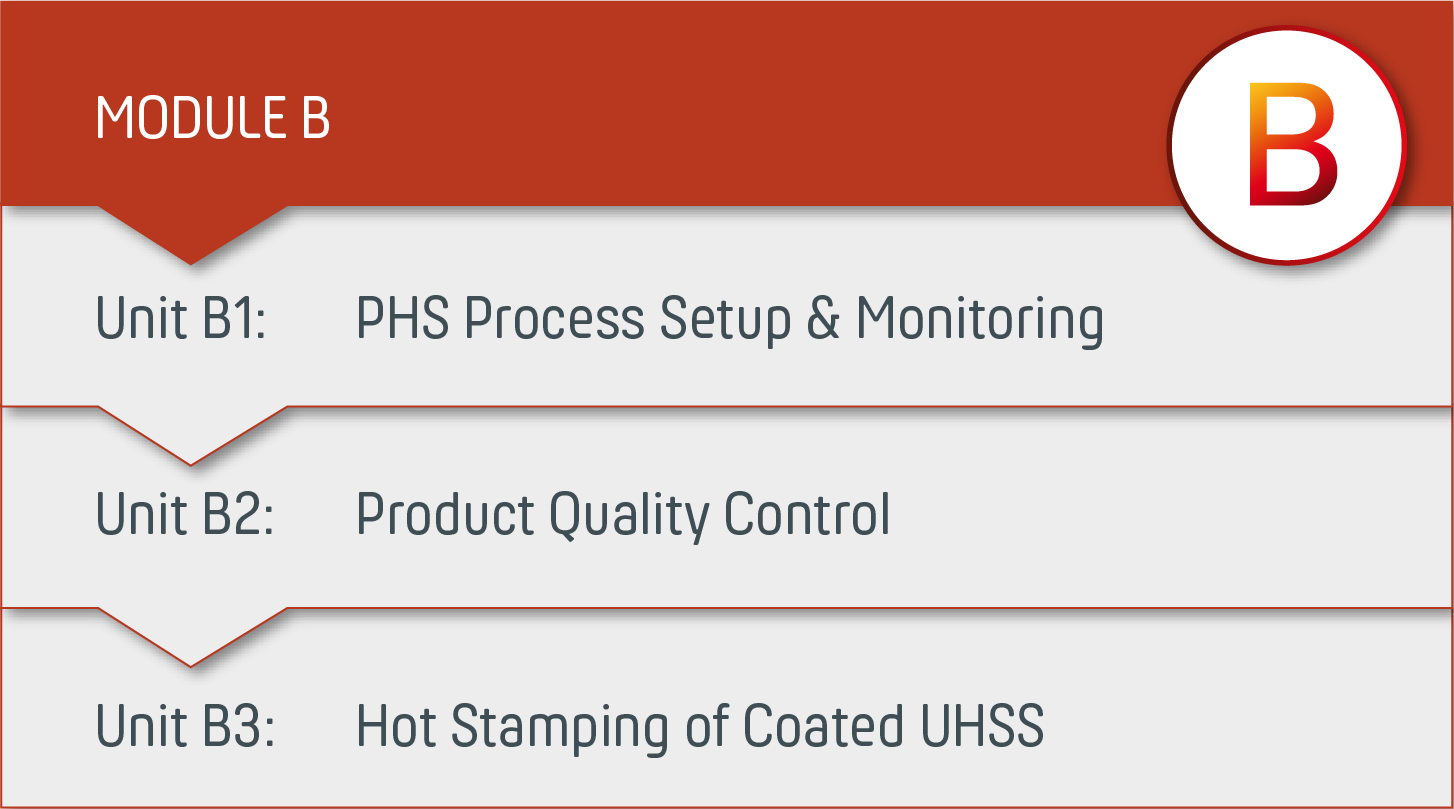

Line-up of learning units of Intensive Training in Press Hardening Module B

Module B training therefore enables participants to acquire hands-on experience and, by this, gaining routine to deliver full performance in daily PHS production.

MODULE C – OPENING THE “BLACK BOX”

Intensive Training in Press Hardening Module C is meant to improve the awareness of those concerned with daily PHS operations on the shop floor level in regards to the specific features of hot stamping production.

Running a PHS production line like a “black box” bears obvious risks. Therefore a basic understanding of the effect of adjustable process parameters and resulting process conditions on the efficiency of the process itself and the quality of final product is absolutely indispensable also and above all for operators being responsible for running a hot stamping line, carrying out lab quality testing, or maintenance of machinery, tools, and dies.

During the training particular attention is drawn to

- heating, cooling & mechanical properties

- coating consistency, roller pollution & surface properties

- tool wear, coolant flow & hot spots

- die spotting, thermal imageing & non-destructive testing.

“The right skills, methods, and equipment protect you from being overrun by complexity!”

Eduard Fuhrmann, PHS Trainer

Line-up of learning units of Intensive Training in Press Hardening Module C

If your hot stamping business has a real global footprint regarding production facilities and product contents, it needs an even stronger organization of knowledge and skills infrastructure. Standardization of equipment and procedures as well as “task forces” for trouble shooting, launch support, inhouse training etc. has to be installed.

To accomplish this, our Intensive Training in Press Hardening Module G has been developed to these specific needs, and, on particular request of “the” market leader.

The course has been designed with a distinctive balance between theory and practice comprising of hands-on experience on a fully equipped PHS production infrastructure, lab internships, seminars and knowledge & skills workshops.

Finally, Module G constitutes an all-inclusive journey from fundamentals to industrial practice covering literally everything from

- fundamentals of heat treatment and hot forming

- development of press hardening technology

- PHS parts in contemporary multi-material architectures

- PHS process strategies & material systems

- functional gradation, tailored property parts & strategies

- process parameter selection & adjustment

- materials testing & consistent process monitoring strategies

- quality management & failure modes.

“At the end of the day, knowledge and skills have to be brought to the production shop floor.”

Alexander Donis, PHS Trainer

Line-up of learning units of Intensive Training in Press Hardening Module G