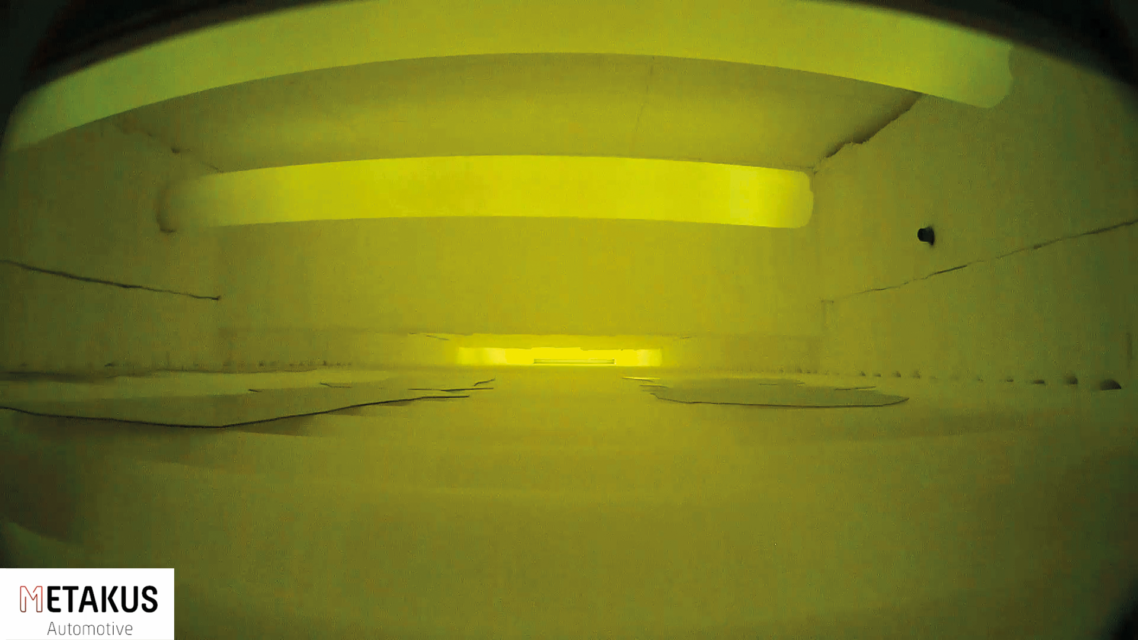

Detects the smallest process changes at highest temperatures!

The product portfolio of furnace inspection systems with integrated temperature sensors, which has been on the market since 2020, is now firmly established and proven as an integral part of real-time process monitoring at almost all leading technology players in the field of press hardening – both OEMs and Tier 1 suppliers. The advantages of these new systems lie not only in their compatibility with all heat treatment systems currently used in series production for press hardening, but above all in their compact design and ease of use. None of the existing users would want to do without the high-resolution images, which provide valuable assistance with the following problems:

- Process disturbances

- Blank displacements

- Thermal distortion of the blanks

- Roller build-up / roller breakage / roller deflection

- Reduction of material waste

- Condition of the heat treatment system and furnace insulation

- Burner defects

- Integrated temperature sensors

- Identification of critical heat treatment zones.

Due to the high system quality, excellent handling and significant process advantages, it is not for nothing that schwartz GmbH, market leader for the manufacture of industrial heat treatment systems in the field of press hardening, among others, advocates the integration of MFI models in industrial roller hearth furnaces.